SOP

STANDARD OPERATING PROCEDURE

LASER WELDING- SOP

| Revision | Date | Initiator | Reviewer Signature | Approver’s Signature |

| 1 | 12 Dec 2017 | Manjunath | Jayabal | MM Nayak |

1.Purpose

This document describes the steps to be followed by the user, to weld components.

2. Scope

It covers the instructions for basic operations of the system, the safety precautions to be followed while operating the system and the penalty, in case of any deviations from following SOP.

3. Points to be noted before starting the tool

-

-

- Check if all the facilities like Coolant water, Argon gas is turned on.

- Never run the laser with the laser protection door opened, by overriding the interlock.

- CNC part program of the component to be ready before starting the machine.

- Clean the mating parts of the components using Acetone and IPA

-

4. Operating Instructions

-

- Sample Loading and welding

-

-

- Load the sample on to the chuck

- Turn-on the laser source, work holding machine and log-in in into the system

- Dry run the part program by disabling the laser to confirm the part program is defect free.

- Activate the laser source and weld the component.

- Any malfunction the emergency switches should be pressed immediately.

- Sample Unloading

- Once the welding process is finished the sample can be removed from the chuck

-

5. Precautions

-

-

- Never run the laser with the laser protection door opened, by overriding the interlock.

- Dry run the part program by disabling the laser to confirm the part program is defect free.

- Activate the laser source and weld the component.

- Any malfunction the emergency switches should be pressed immediately.

-

6. Contact Point

If you feel any difficulty while operating or any issue with the tool. Please contact the tool owners

Manjunath: 9731387979

Jaybal: 9886058035

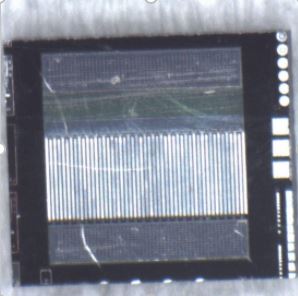

Laser Tool pictures:

If any other than above stated, Please contact the tool owner.

NOTE:

Any deviations from this SOP will be considered as a breach of User Agreement conditions and will result in cancellation of access to the tool.

HIGH PRESSURE HYDRAULIC CALIBRATOR - SOP

| Revision | Date | Initiator | Reviewer | Approver’s Signature |

| 1 | 21 Dec 2017 | Manjunath | Pavitra /Manjunath | MM Nayak |

1. Purpose

This document describes the steps to be followed by the user, to calibrate pressure sensor device.

2. Scope

It covers the instructions for basic operations of the system, the safety precautions to be followed while operating the system and the consequences, in case of any deviations from following SOP.

3. Points to be noted before starting the tool

-

-

- Make sure beforehand the device is leak proof and can withstand high pressures at-least 1.5 times the actual operating pressure.

- Mount the device with appropriate fittings and ‘O’ rings, only hand tight the device.

- Release the relief valve and prime the tool by pressurizing and depressurizing and verify that there are no air bubbles.

-

4. Operating Instructions

-

- Sample Loading and welding

- Mount the sensor always upright and do a leak test at low pressures and close the relief valve.

- Gradually increase/decrease the pressure/depressurizing by adding /removing the weights in suitable increments and calibrate the sensor.

- Sample Unloading

- Make sure to unload the component only after depressurizing and opening of the relief valve.

- Sample Loading and welding

5. Precautions

In-case of any emergency depressurize and open the relief valve

6. Contact Point

If you feel any difficulty while operating or any issue with the tool. Please contact the tool owners

Pavitra: 9449947188

Manjunath: 9731387979

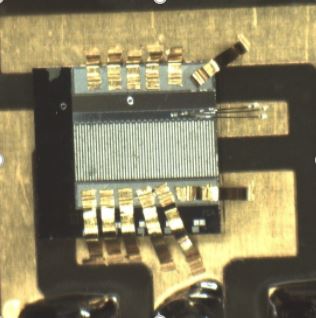

Equipment pictures:

If any other than above stated, Please contact the tool owner.

NOTE:

Any deviations from this SOP will be considered as a breach of User Agreement conditions and will result in cancellation of access to the tool.

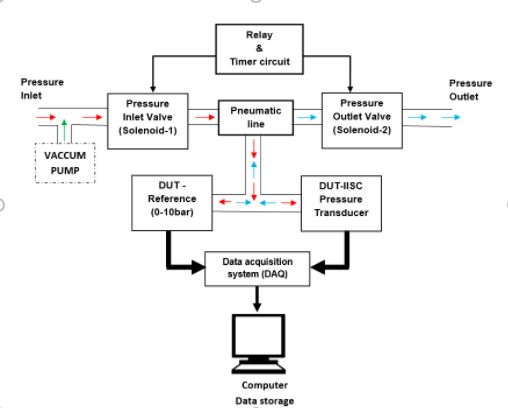

HIGH PRESSURE PNEUMATIC CALIBRATOR - SOP

| Revision | Date | Initiator | Reviewer | Approver’s Signature |

| 1 | 12 Dec 2017 | Manjunath | Shankaran /Manjunath | MM Nayak |

1.Purpose

This document describes the steps to be followed by the user, to calibrate pressure sensor.

2. Scope

It covers the instructions for basic operations of the system, the safety precautions to be followed while operating the system and the consequences, in case of any deviations from following SOP.

3. Points to be noted before starting the tool

-

-

- Cordon off the area around the tool.

- Mount the device with appropriate fittings and point the device away from operator.

- Make sure beforehand the device is leak proof and can withstand high pressures at-least 1.5 times the actual operating pressure.

-

4. Operating Instructions

-

- Sample Loading and welding

- Mount the sensor which has to be calibrated and do a leak test at lower pressures (10-20) bar and slowly increase the pressure by closing the input check valve and check for any pressure drop.

- Increase the pressure gradually up to 300 bar and close the release valve and turn off the compressor.

- Ascending pressure test – Test the sensor by gradually increasing adjusting the pressure regulator to the required steps of pressure

- Descending pressure test – by gradually releasing the pressure using the pressure release valve in the required steps.

- Sample Unloading

- Once the calibration is completed depressurize by opening the relief valve completely and unload the sample.

- Sample Loading and welding

5. Precautions

-

-

- In-case of any emergency turnoff the Maximator Compressor and release the pressure immediately by turning the pressure release valve.

-

6. Contact Point

If you feel any difficulty while operating or any issue with the tool. Please contact the tool owners

Sankaran: 9632839996

Manjunath: 9731387979

Equipment pictures:

If any other than above stated, Please contact the tool owner.

NOTE:

Any deviations from this SOP will be considered as a breach of User Agreement conditions and will result in cancellation of access to the tool